CNC Boring Bars

All of our bars are comprehensively tested and used by us on our own lathes.

Developing

Over four years ago, we started developing boring bars for particular applications in our shop. Standard boring bars were doing the job, but in some cases, there was a definite need for something better. We have developed and refined our boring bars, and over the past eighteen months have been selling them to very satisfied machine shops. Having hands on experience has helped us target and identify where improvements would benefit the user in more ways than one. All of our bars are comprehensively tested and used by us on our own lathes. So what benefits can our boring bars bring into your shop? Let us examine the problems we faced and then the features of the bars and benefits realised.

Boring Problems

Probably the number one issue with boring is chatter and vibration in the bore of the workpiece. Fine tolerances demand excellent surface finishes. A good understanding of correct speeds, feeds, and depth of cut for the material concerned is necessary. This is a given. Chip evacuation can be troublesome, more so when boring out a blind hole. This is compounded by the rotational speed of the work, which generally throws the chips against the bore by centrifugal force. Where the coolant is directed from the tool block, as the bar progresses into the bore, the coolant is directed against the outer diameter of the work, missing the boring bar completely. Further, up to that stage, the coolant is in fact forcing the chips back into the bore, making things a lot worse. Boring blind holes requires inventive programming, with the tool being retracted off the job, spindle stopped, hole cleaned out, and then letting the cycle continue. Obviously, there are many ways around this situation, as we all program following our own methods.

Solid one piece construction

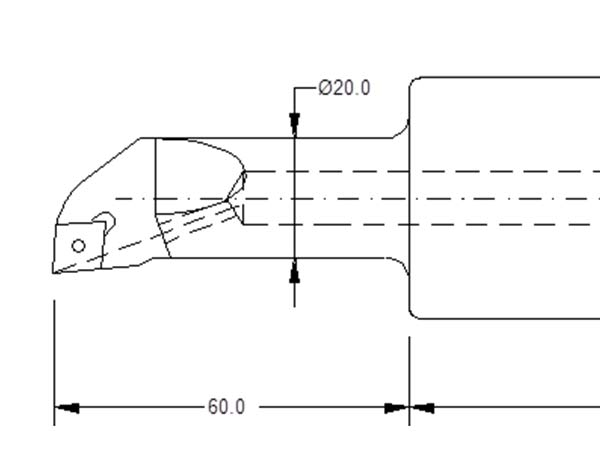

This eliminates the usual sleeve adaptor which can promote vibration. As the main body is a fixed length, the possibility of a bar protruding out of the rear of the toolblock and colliding with the turret body when indexing is eliminated. The larger diameter allows for an increased contact area for clamping, thus enhancing rigidity.

Minimal Overhang

Combined with a generous fillet radius, promotes strength and stability.

CCMT Positive Insert

Lower cutting forces reduce vibrational tendencies. Also save on insert costs on larger finishing bars. Why use a large finishing insert when the depth of cut is 0.2—0.5mm?

Internal Coolant

The coolant is directed from the rear of the bar directly to the corner of the insert. This feature promotes the life of the insert, (more pieces per corner), and assists to evacuate chips from the bore. This also keeps the workpiece cooler, with more consistent results.

Save money Make money!

We made this bar to utilise the two normally unused corners of the CCMT insert. If you have a box of normally used inserts, then you already have free inserts! Due to the nature of the insert, this can only be used for straight boring work, not shoulders, or facing. We use it for roughing out bores in flanges

DCMT Bars

We made this bar for finish profiling and it works very well, also exhibiting good insert life. This specially made bar is 41mm diameter, with the insert protruding from the bar less than usual. We made this finishing bar to special order, to machine 316 stainless steel.

Hydraulic actuator

A hydraulic actuator designed and manufactured by Heathcote Engineering to a customers requirements.