CNC Turning and Milling

We have three CNC turning centres with 8”, 10”, and 12” chucks. A comprehensive array of tooling allows us to tackle many kinds of work.CNC Turning and Milling

Materials

We handle most of the usual materials such as EN8, En9 steels, cast iron, aluminium, 304, 316 stainless steels, as well as most plastics such as nylon, pvc, polyprop, HDPE, and so on. We also accept castings for machining as well.

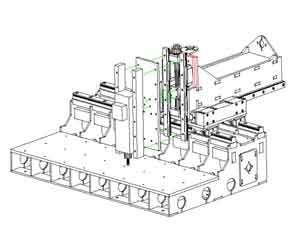

CNC milling

Our CNC milling machines handle all of the usual milling and drilling operations, and our recently acquired mill, has a fully integrated fourth axis, which allows us to take on more complex milling work.

CNC turning

We have three CNC turning centres with 8”, 10”, and 12” chucks. A comprehensive array of tooling allows us to tackle many kinds of work.

Minimum order

Our minimum order quantity is 20 off, although we machine smaller quantities by agreement.

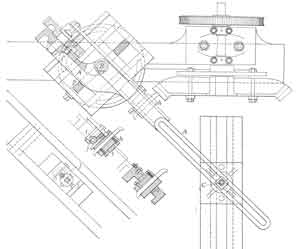

Drawings

We can work from samples supplied by our customers. A sample part may be new, or worn. Where a drawing is not available, we prepare drawings of the part for your approval before commencing work. In this way, we eliminate conflict concerning dimensions and tolerances. The end result is a part that is correct and fit for use.

Design

We are able to design components to work properly. By involving the machining processes from the design stage, many problems can be eliminated. This saves unnecessary expense and time and gets the job to production sooner. Remember that the final drawing will determine the true cost per part.

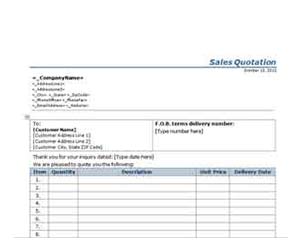

Quotations

In order to prepare fast accurate quotations, we use QUOTECAM, a software application that takes into account all aspects of machining components. By using QUOTECAM we are able to offer the customer an accurately costed quotation.

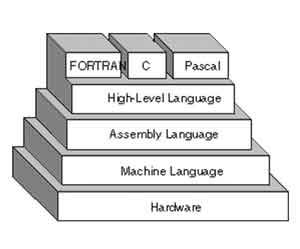

Programming

To enable us to generate code for the CNC machines, we utilise EDGECAM software. This allows us to optimise toolpaths, perform simulations, and give the shortest machine time per component.